Earthing Line Welding and Accessories

EGYCARBON uses Graphite in Earthing line welding to ensure that the metal enclosure of the welding machine and ground is at the same potential. Thus providing maximum safety to users.

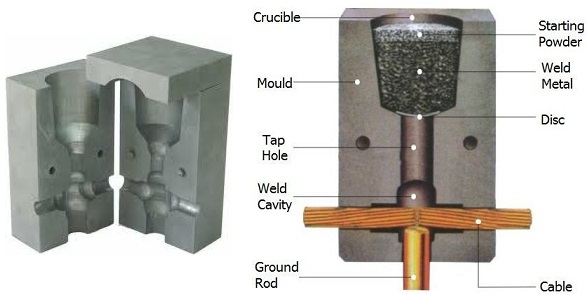

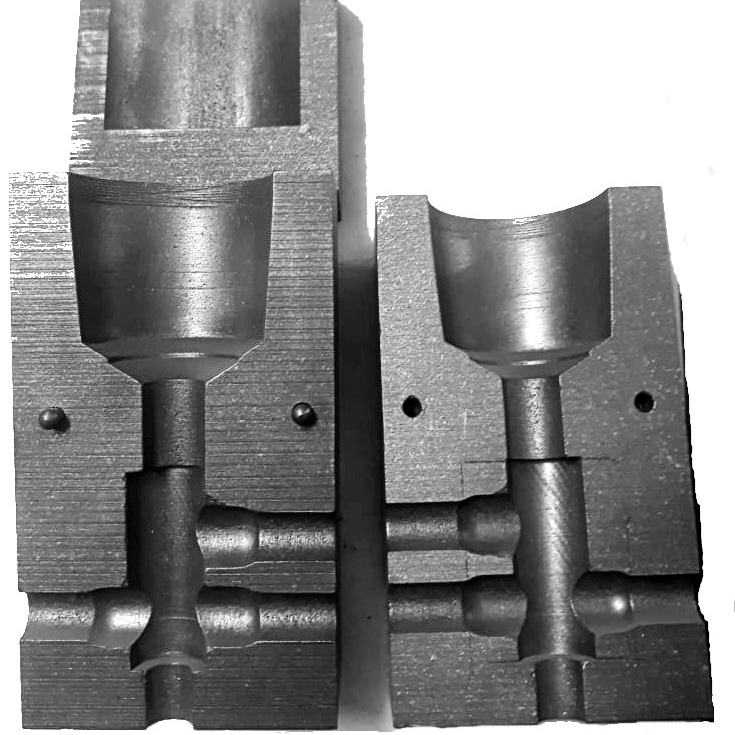

The welding process uses the high temperature reaction of copper oxide and aluminium within a semi-permanent graphite mould to form electrical connections mainly between copper to copper or copper to steel.

Connections are tolerant to repeated fault currents, highly conductive, permanent and demonstrate excellent corrosion resistance – most exothermic connections have at least twice the cross-sectional area of the earthing conductors being jointed.

Importance of Graphite in Exothermic welding:

- Thermal Shock Resistance

- High thermal conductivity

- Dry Lubrication properties